Electrical Whips

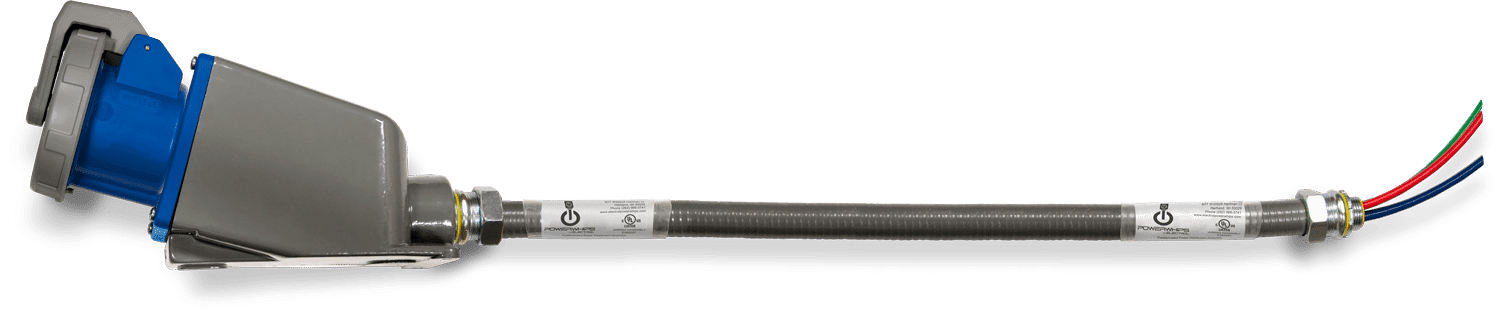

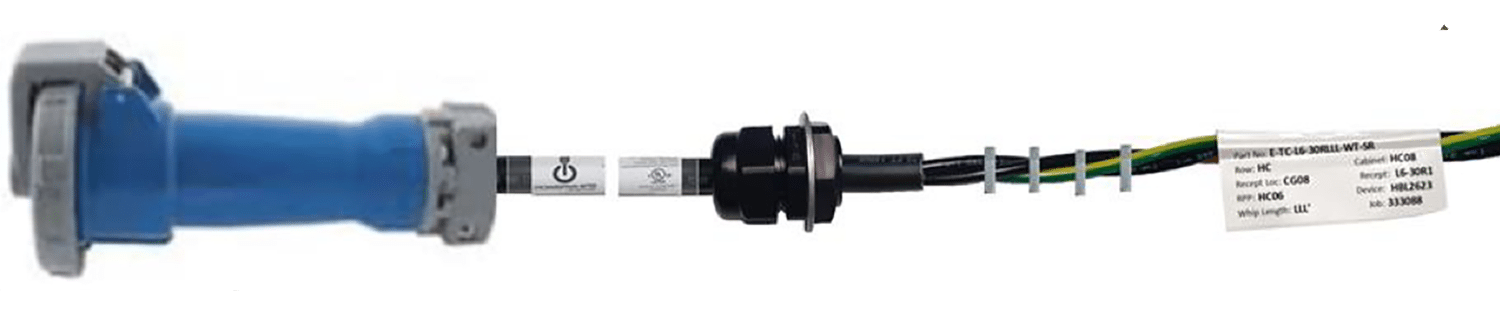

IEC Pin and Sleeve

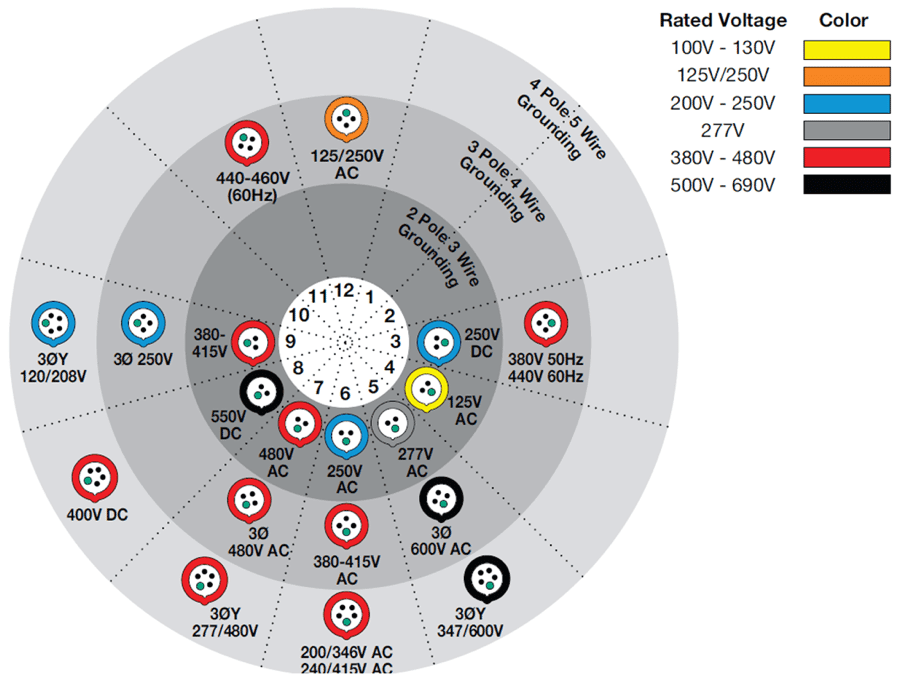

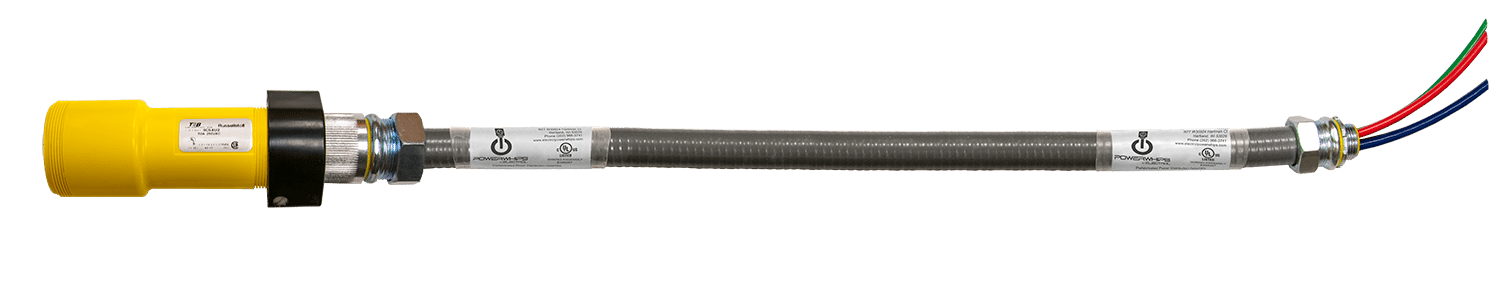

IEC 60309 Pin and Sleeve electrical whip products are designed and manufactured to meet the International Standard IEC 60309-1 and IEC 60309-2. This device standard calls out a singly rated, non-interchangeable configuration for every voltage and type of service throughout the world. Pin and sleeve device housings are color coded by voltage rating. The voltage is determined by the location of the female ground contact relative to the housing keyway. Simply by manufacturing the device with a ground contact in a certain “clock” position, the device will be rated for a particular voltage system. The diagram shows the keying position and the color coding that is associated with each voltage.

IEC Pin and Sleeve Features

- IEC Pin and Sleeve PowerWhips are UL Listed and labeled as a “Prefabricated Power Distribution Assembly”

- IEC Pin and Sleeve PowerWhips are manufactured in accordance to the National Electrical Code “NEC”

- All materials used in the construction of PowerWhips are UL Listed and new from the factory

- IEC Receptacles, inlets, connectors and plugs are available based on voltage / amperage requirements

- IEC devices have a rugged one-piece housing, thick wall construction protects internal components, eliminates joints preventing infiltration of contaminants

- IEC devices have heavy duty external cord grips to provide maximum cord retention to maintain secure terminations

- Sequential contact engagement, ground makes first and breaks last. Neutral makes second and breaks second (to prevent a momentary over-voltage on components connected phase to neutral)

- Typically ships in 1-3 days

- Inventory programs available

- Online PowerWhip configurator

- Minimizes workload at the job site

- Testing to UL safety standard, 100% testing

- PowerWhips and whip tails are cut to the exact length specification

IEC Pin and Sleeve Extras

- LFMC conduit available in Type LA, ATLA, CBLA and ZHLA

- Eleven liquid tight colors help distinguish primary power from redundant power

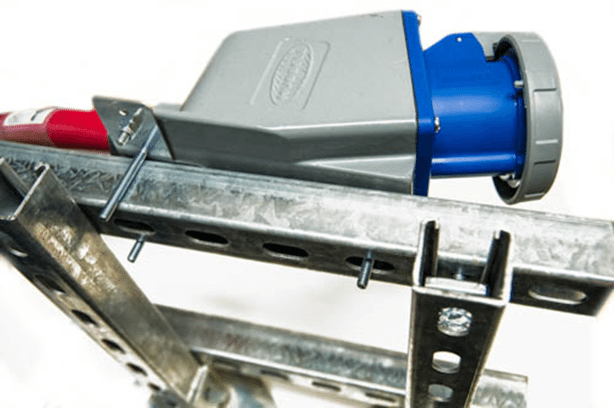

- Back boxes and conduit adapter kits

- Custom PowerWhip labeling

- Wire color “Phasing” options

- Standard wire bundling

- Engineering support (job take-offs at no charge)

- Custom packaging

- Fill out attached configurator and email to sales@amcoenclosures.com

- Send an email to sales@amcoenclosures.com with PowerWhip requirements

- Call AMCO Enclosures at 847-391-8100 and ask for sales

IEC Pin and Sleeve Accessories

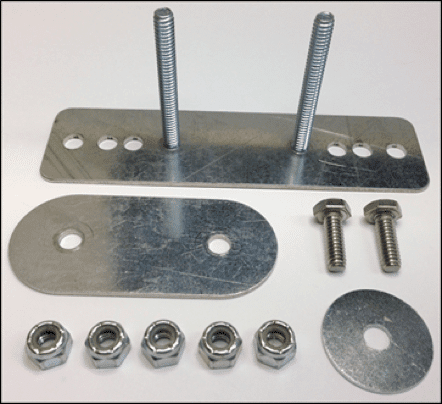

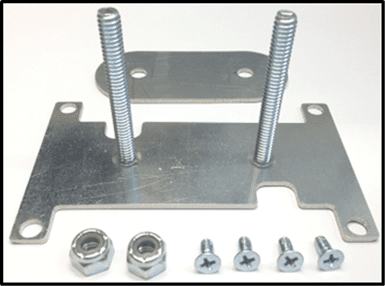

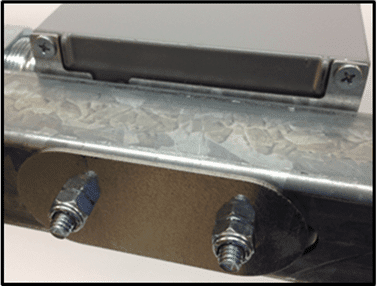

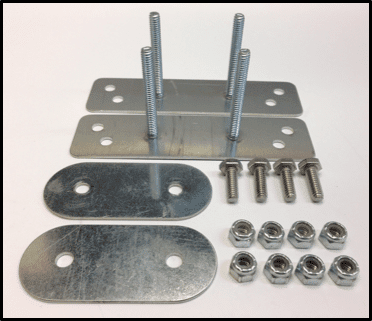

Mounting Kits:

IEC Back Box

IEC Connector

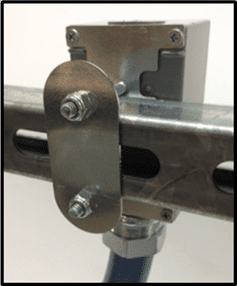

Conduit Mounting

Circuit Breakers:

Circuit Breakers

- Square D - QOB, QOB-VH, QO and QO-VH

- Eaton C-H - BAB and QBHW

- GE - THQB and THHQB

- ABB - Pro-Line

Air Flow Management:

Air Flow Management

- KoldLok

- HotLok

Monitoring:

Monitoring

- Packet Power

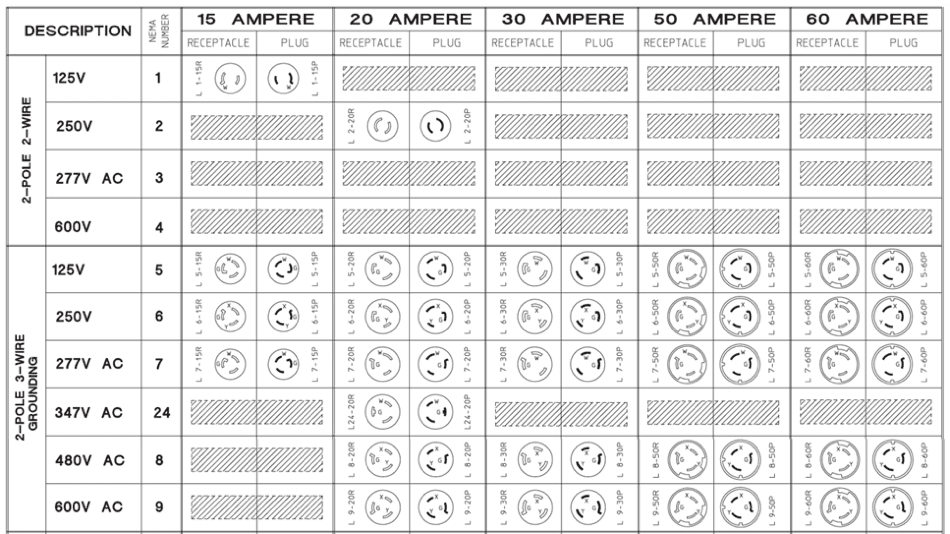

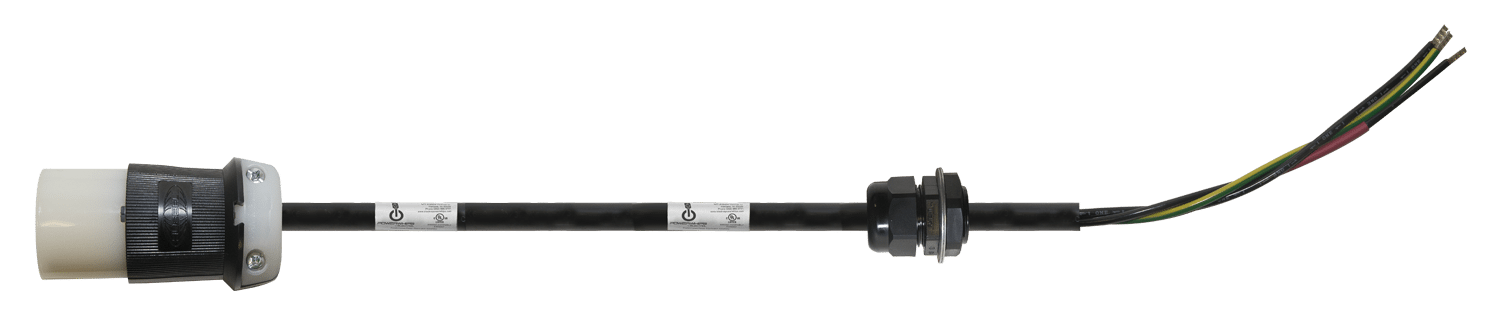

NEMA

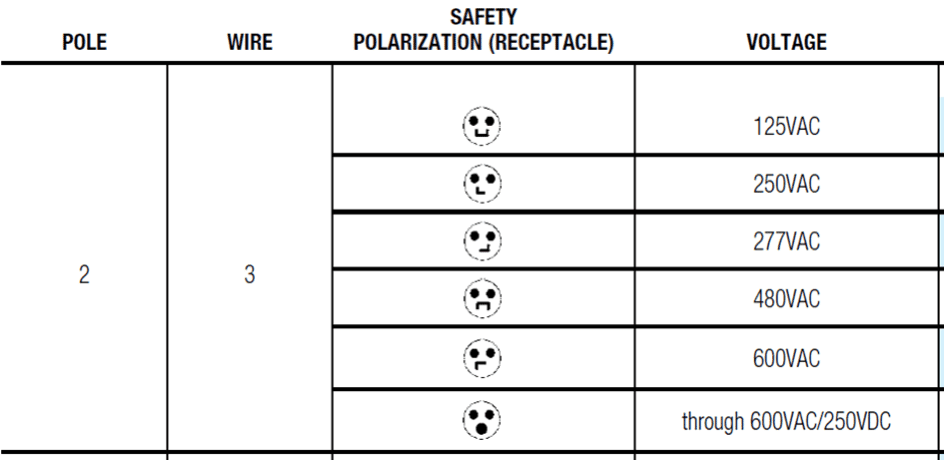

NEMA wiring devices are made in current ratings from 15 to 60 amperes (A), with voltage ratings from 125 to 600 volts (V). Different combinations of contact blade widths, shapes, orientation, and dimensions create non-interchangeable connectors that are unique for each combination of voltage, electric current carrying capacity, and grounding system. There are two basic classifications of NEMA devices: straight-blade and locking. Numbers prefixed by ‘L’ are curved-blade, twist-locking devices; others without a leading ‘L’ are straight blade and non-locking.

NEMA Features

- NEMA PowerWhips are UL Listed and labeled as a “Prefabricated Power Distribution Assembly”

- NEMA PowerWhips are manufactured in accordance to the National Electrical Code “NEC”

- All materials used in the construction of PowerWhips are UL Listed and new from the factory

- NEMA receptacles, inlets, connectors and plugs are available based on voltage / amperage requirements

- NEMA devices are available in straight blade, locking blade, isolated ground blade and CA 50A blade

- NEMA PowerWhips can have multiple devices in a box with multiple circuits

- NEMA devices have heavy duty external cord grips to provide maximum cord retention to maintain secure terminations

- NEMA locking devices provide a more reliable connection that helps prevent accidental disconnection by vibration

- Typically ships in 1-3 days

- Inventory programs available

- Online PowerWhip configurator

- Minimizes workload at the job site

- Testing to UL safety standard, 100% testing

- PowerWhips and whip tails are cut to the exact length specification

NEMA Extras

- LFMC conduit available in Type LA, ATLA, CBLA and ZHLA

- Eleven liquid tight colors help distinguish primary power from redundant power

- Back boxes and conduit adapter kits

- Custom box painting

- Custom PDU PowerWhip labeling

- Wire color “Phasing” options

- Standard wire bundling

- Engineering support (job take-offs at no charge)

- Custom packaging

- Fill out attached configurator and email to sales@amcoenclosures.com

- Send an email to sales@amcoenclosures.com with PowerWhip requirements

- Call AMCO Enclosures at 847-391-8100 and ask for sales

NEMA Accessories

Mounting Kits:

NEMA Back Box

Circuit Breakers:

Circuit Breakers

- Square D – QOB, QOB-VH, QO and QO-VH

- Eaton C-H – BAB and QBHW

- GE – THQB and THHQB

- ABB – Pro-Line

Monitoring:

Monitoring

- Packet Power

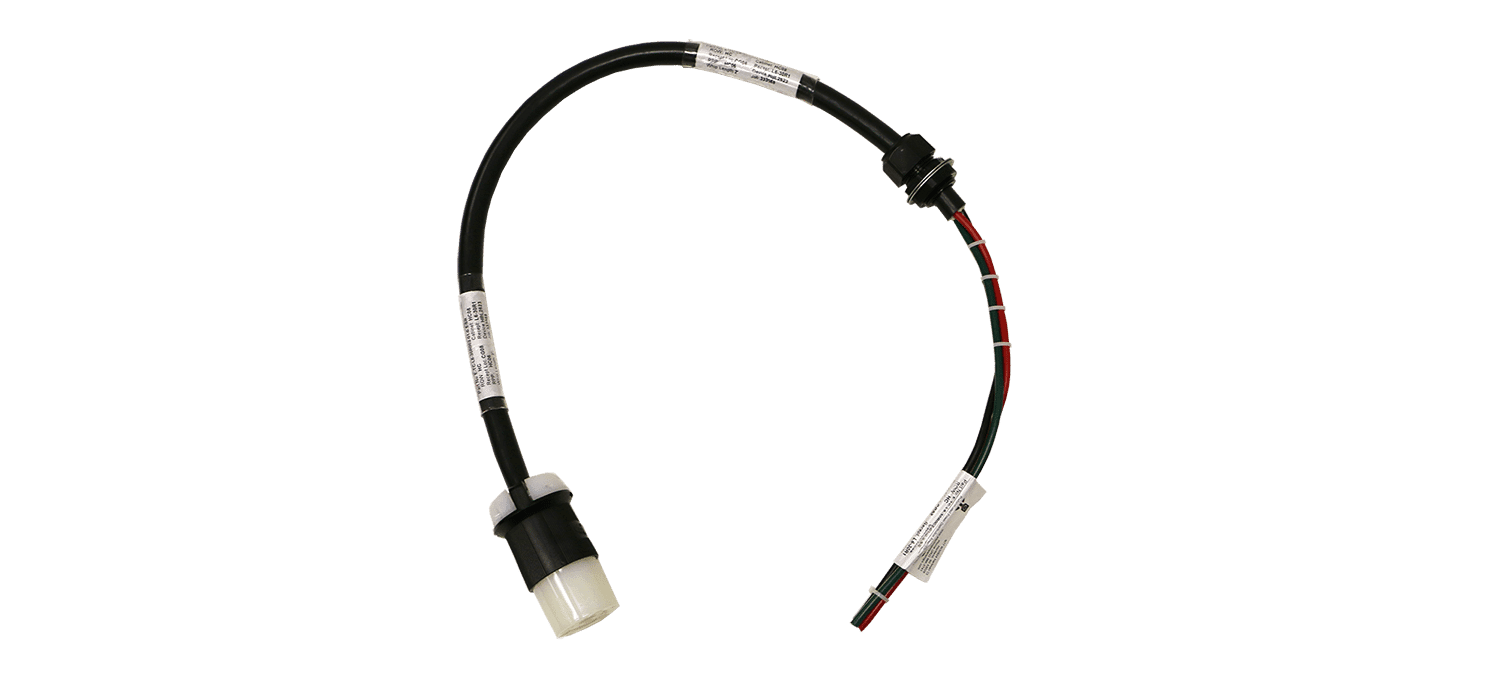

Russellstoll

Russellstoll (RS) Pin and Sleeve products have a proprietary pin pattern that is singly rated, non-interchangeable configuration for voltage and type of service to connect only to another Russellstoll device. The Russellstoll MaxGard product is a metal device while the Russellstoll DuraGard product is a thermoplastic device. Both types of devices are rated and polarized for specific voltages and amperages to prevent dangerous mismating of devices of different ratings.

Russellstoll Features

- RS Pin and Sleeve PowerWhips are UL Listed and labeled as a “Prefabricated Power Distribution Assembly”

- RS Pin and Sleeve PowerWhips are manufactured in accordance to the National Electrical Code “NEC”

- All materials used in the construction of PowerWhips are UL Listed and new from the factory

- RS receptacles, inlets, connectors and plugs are available based on voltage / amperage requirements for electrical whips.

- RS devices are durable and UL® 94-V0 flame rated with DuraV® high-impact body and collars, thermoset interiors and dead front constructions

- RS devices have a neoprene compression bushing cable locking system with a locking bushing nut with external cable clamps

- RS devices are designed with the safety ground makes first breaks last and voltage polarized to meet NEC® 210-7 and OSHA standards

- Typically ships in 3-5 days

- Inventory programs available

- Online PowerWhip configurator

- Minimizes workload at the job site

- Testing to UL safety standard, 100% testing

- PowerWhips and whip tails are cut to the exact length specification

Russellstoll Extras

- LFMC conduit available in Type LA, ATLA, CBLA and ZHLA

- Eleven liquid tight colors help distinguish primary power from redundant power

- Back boxes and conduit adapter kits

- Custom PowerWhip labeling

- Wire color “Phasing” options

- Standard wire bundling

- Engineering support (job take-offs at no charge)

- Custom packaging

- Fill out attached configurator and email to sales@amcoenclosures.com

- Send an email to sales@amcoenclosures.com with PowerWhip requirements

- Call AMCO Enclosures at 847-391-8100 and ask for sales

Russellstoll Accessories

Mounting Kits:

RS Back Box

RS Connector

Conduit Mounting

Circuit Breakers:

Circuit Breakers

- Square D – QOB, QOB-VH, QO and QO-VH

- Eaton C-H – BAB and QBHW

- GE – THQB and THHQB

- ABB – Pro-Line

Air Flow Management:

Air Flow Management

- KoldLok

- HotLok

Monitoring:

Monitoring

- Packet Power

Data Center Overhead

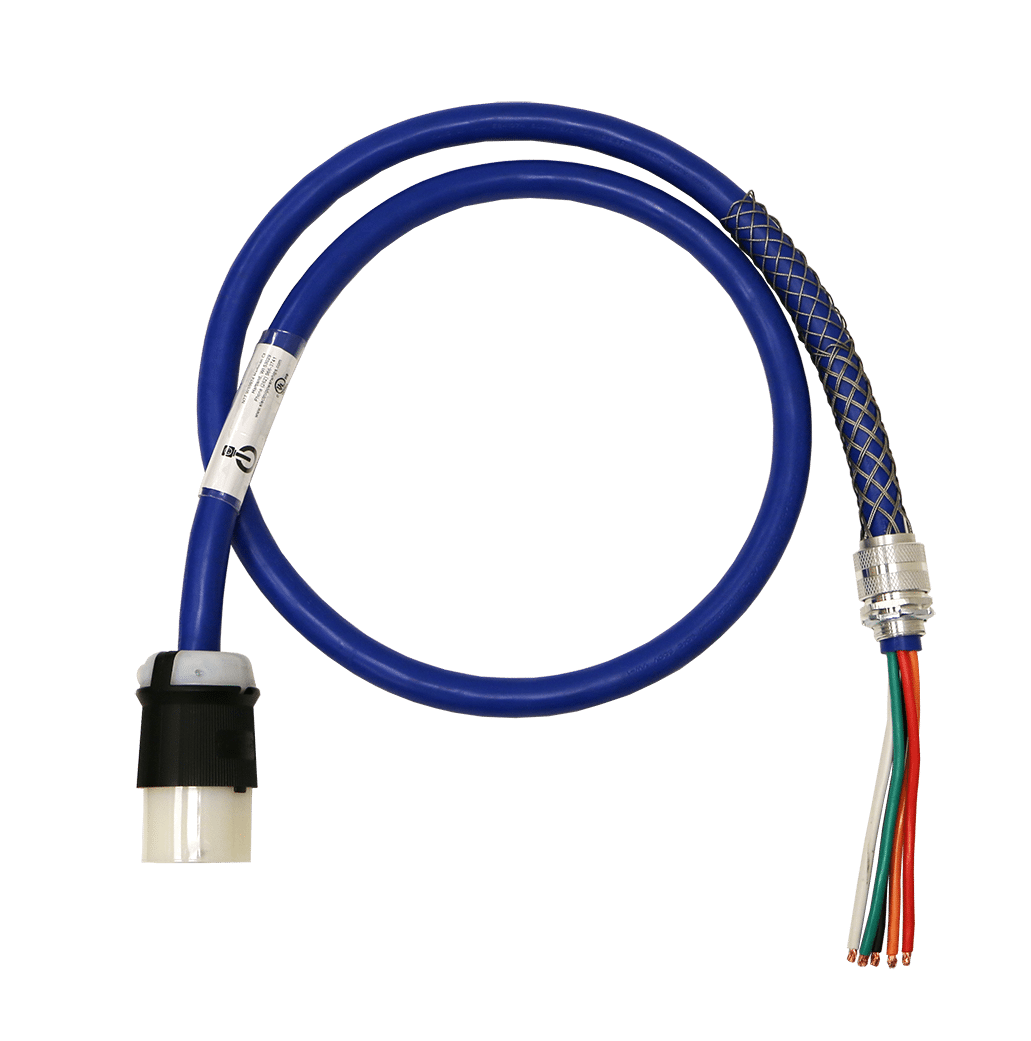

Tray Cable

Tray Cable TC (Type TC) is defined by the National Electric Code as “a factory assembly of two or more insulated conductors, with or without associated bare or covered grounding conductors under a nonmetallic sheath, for installation in cable trays, in raceways, or where supported by a messenger wire and rated for 600 volts.” An extension to the tray rated cable, is an exposed run (ER) rating. Type TC-ER cable complies with the crush and impact requirements of metal-clad cable. It can be used when dropping out of cable tray to equipment or devices, and also where dropping from tray to tray. Section 336.10(7) of the 2014 National Electrical Code (NEC) is clear that cable with only a TC rating cannot be run unprotected outside a raceway or cable tray. The Type TC-ER cable can be used up to 50 feet past the cable tray without having additional armor or be held within a tray. Type TC-ER cable with IEC Pin and Sleeve, NEMA and Russellstoll devices are UL Listed available assemblies.

Tray Cable Features

- Tray Cable PowerWhips are UL Listed and labeled as a “Prefabricated Power Distribution Assembly” (UL44 & UL1277)

- Tray Cable PowerWhips are manufactured in accordance to the National Electrical Code “NEC” (Sec. 366.10(7) & 725.46(B)(4)(2))

- All materials used in the construction of PowerWhips are UL Listed and new from the factory

- IEC / NEMA / Russellstoll receptacles, inlets, connectors and plugs are available based on voltage / amperage requirements

- NEMA devices are available in straight blade, locking blade, isolated ground blade and CA 50A blade

- IEC / NEMA / Russellstoll devices have heavy duty external cord grips to provide maximum cord retention to maintain secure terminations

- IEC / NEMA / Russellstoll locking devices provide a more reliable connection that helps prevent accidental disconnection by vibration

- Typically ships in 1-3 days

- Inventory programs available

- Minimizes workload at the job site

- Testing to UL safety standard, 100% testing

- Tray Cable PowerWhips and whip tails are cut to the exact length specification

Tray Cable Extras

- Type TC-ER cable

- Cable “grips” and “strain relief connectors” available

- Wire color “Phasing” options

- Standard wire bundling

- Engineering support (job take-offs at no charge)

- Custom packaging

- Fill out attached configurator and email to sales@amcoenclosures.com

- Send an email to sales@amcoenclosures.com with PowerWhip requirements

- Call AMCO Enclosures at 847-391-8100 and ask for sales

Tray Cable Accessories

Circuit Breakers:

Circuit Breakers

- Square D – QOB, QOB-VH, QO and QO-VH

- Eaton C-H – BAB and QBHW

- GE – THQB and THHQB

- ABB – Pro-Line

Air Flow Management:

Air Flow Management

- KoldLok

- HotLok

Monitoring:

Monitoring

- Packet Power

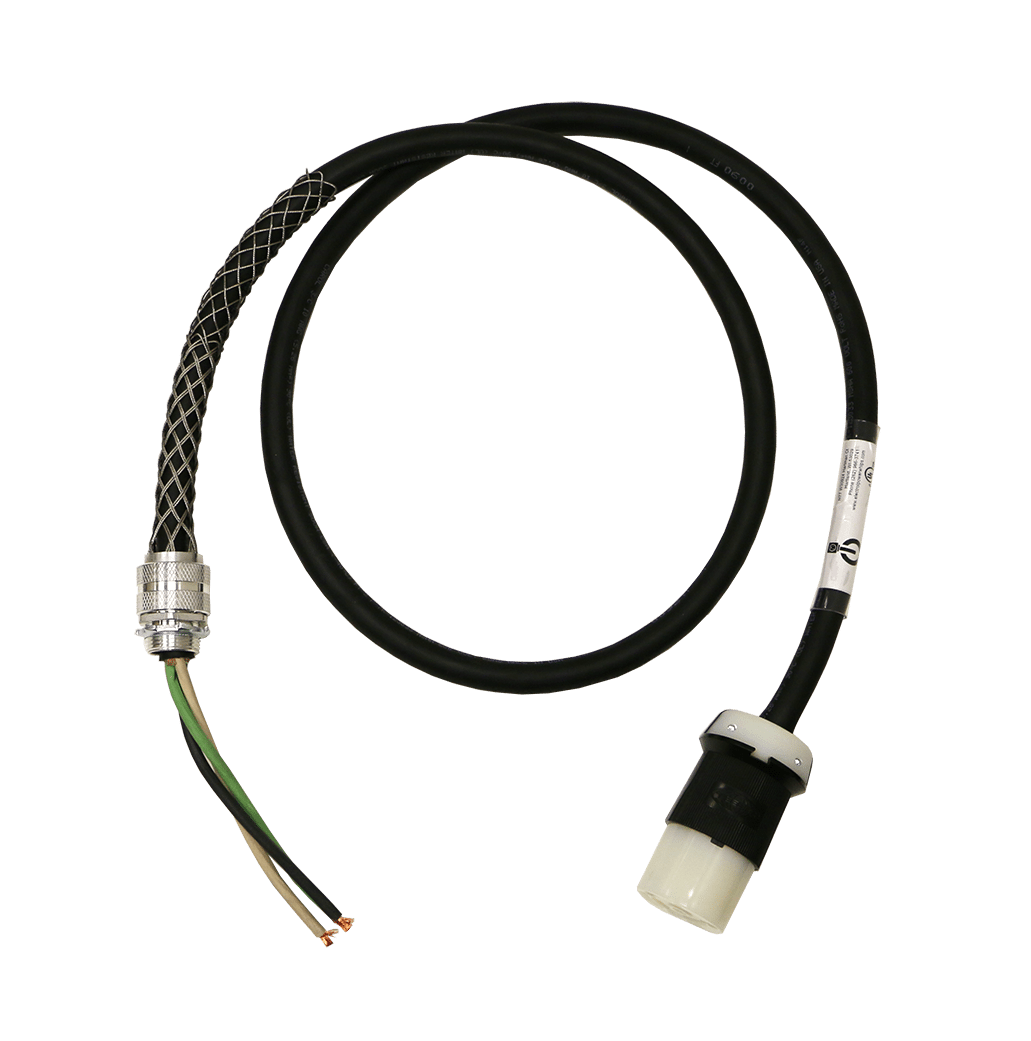

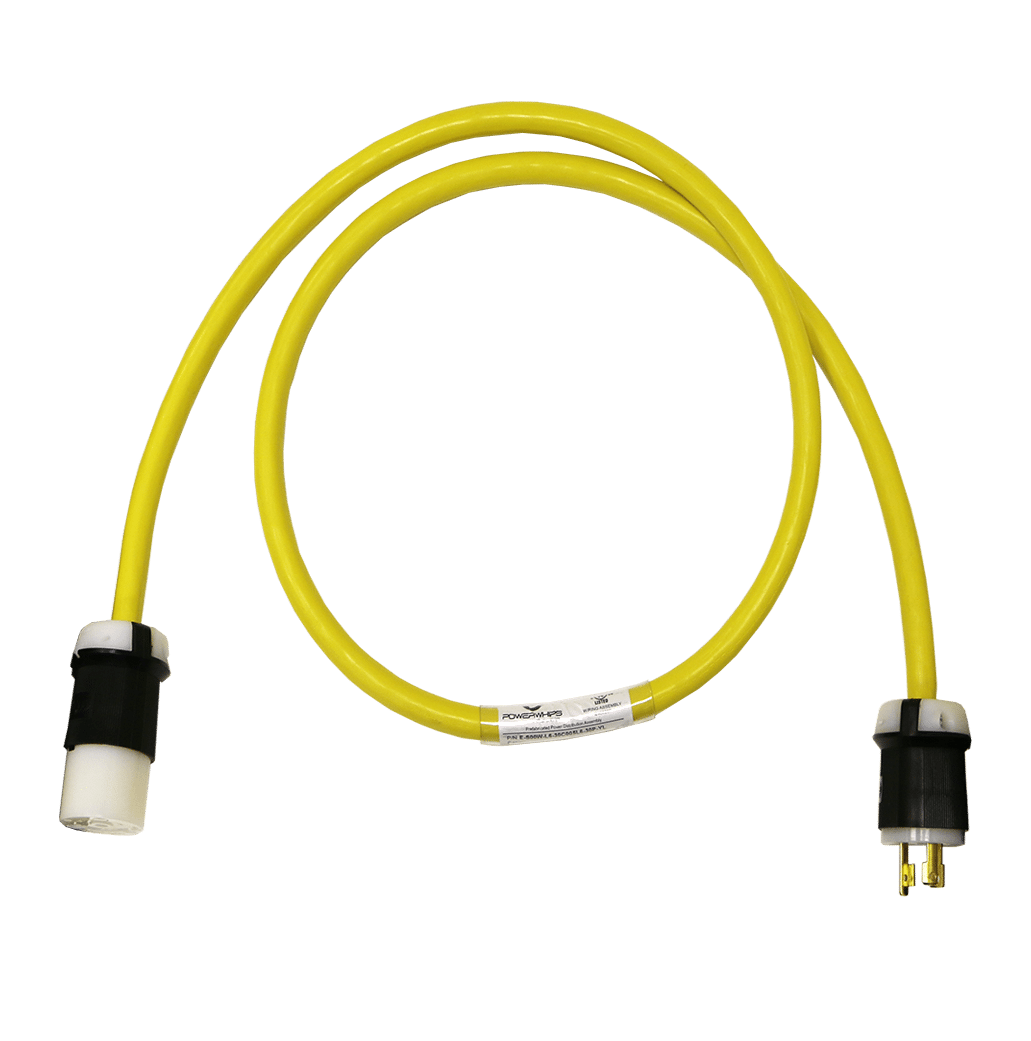

SOOW Cords

Portable electrical whip cord usually contains two or more flexible, stranded copper conductors, in gauge sizes from No. 18 AWG through No. 2 AWG. The copper stranding and types of compounds in the insulation and jacket dictate the flexibility and strength of the cord. The jacket and insulation are key to its physical, chemical, and electrical properties. UL and CSA designations for these cords are SOOW. Thermoset TYPE SOOW cord is for use in heavy-duty industrial applications where flexibility and durability is required. SOOW cord is resistant to cuts, tears, abrasions, and chemicals. SOOW’s best features are its temperature and oil-resistant properties which will not melt when in contact with heated objects or oils: up to 221 DEGRF (105 DEGRC). In temperatures as low as 40 DEGRF below zero, SOOW maintains its flexibility, durability, and resistance to cracking during normal handling. Type SOOW cord stands for: S = Service Cord (600 Volts) OO = Oil Resistant both inside insulation and outside jacket. W = CSA designation for weather/water resistance. SOOW cord with IEC Pin and Sleeve, NEMA and Russellstoll devices are UL Listed available assemblies.

SOOW Cords Features

- SOOW PowerWhip cords are UL Listed and labeled as a “Non-Detachable Power Supply Cord” (UL817)

- SOOW PowerWhip cords are manufactured in accordance to the National Electrical Code “NEC” (Art. 400)

- All materials used in the construction of PowerWhips are UL Listed and new from the factory

- IEC / NEMA / Russellstoll receptacles, inlets, connectors and plugs are available based on voltage / amperage requirements

- NEMA devices are available in straight blade, locking blade, isolated ground blade and CA 50A blade

- IEC / NEMA / Russellstoll devices have heavy duty external cord grips to provide maximum cord retention to maintain secure terminations

- IEC / NEMA / Russellstoll locking devices provide a more reliable connection that helps prevent accidental disconnection by vibration

- Typically ships in 1-3 days

- Inventory programs available

- Minimizes workload at the job site

- Testing to UL safety standard, 100% testing

- SOOW PowerWhip cords and whip tails are cut to the exact length specification

SOOW Cords Extras

- Three SOOW cord colors help distinguish primary power from redundant power for electrical whips.

- Cord “grips” and “strain relief connectors” available

- Wire color “Phasing” options

- Standard wire bundling

- Engineering support (job take-offs at no charge)

- Custom packaging

- Fill out attached configurator and email to sales@amcoenclosures.com

- Send an email to sales@amcoenclosures.com with PowerWhip requirements

- Call AMCO Enclosures at 847-391-8100 and ask for sales

SOOW Cords Accessories

Circuit Breakers:

Circuit Breakers

- Square D – QOB, QOB-VH, QO and QO-VH

- Eaton C-H – BAB and QBHW

- GE – THQB and THHQB

- ABB – Pro-Line

Air Flow Management:

Air Flow Management

- KoldLok

- HotLok

Monitoring:

Monitoring

- Packet Power