Product Image Gallery

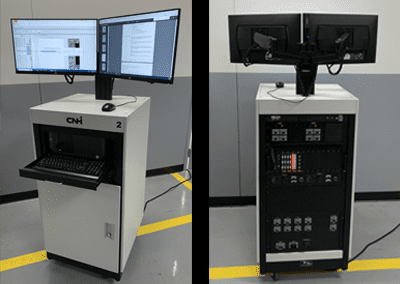

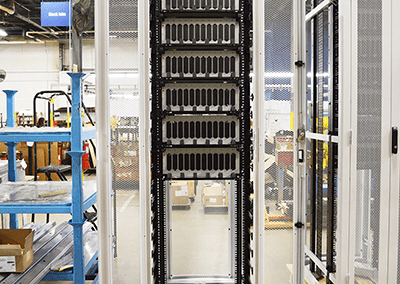

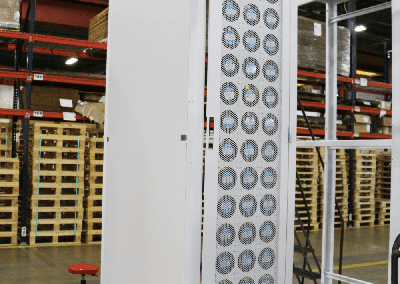

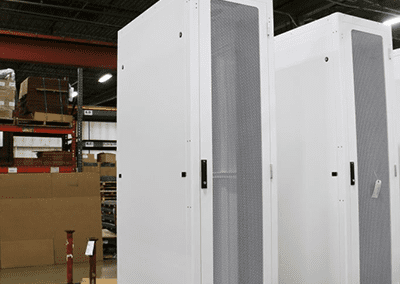

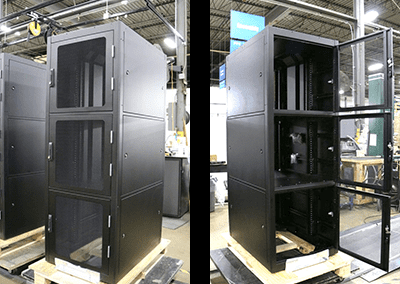

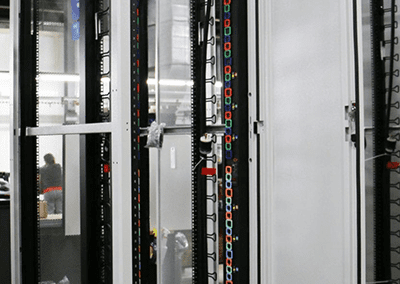

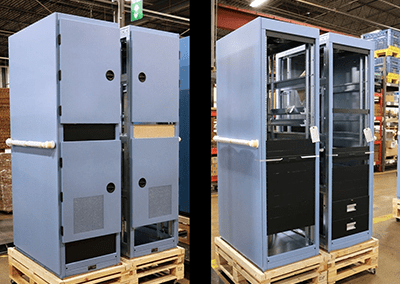

One of the things AMCO Enclosures takes satisfaction in is being the only server rack and cabinet manufacturer in the US. And how do we challenge ourselves to be even better than the rest? By offering a product image gallery showcasing a wide range of custom enclosures and data racks built to match your business’s exact needs. Our emphasis on customization allows us to offer a distinct range of sizes, heights, and colors to meet your specific requirements. We strongly believe that customization is a standard industry’s need to get what they need most from their data rack and enclosures. Looking closer at our product image gallery, you’ll find our products showing in-depth attention to detail, highlighting our promise to manufacture products of the highest caliber and durability. Explore our images to learn more about our expertly crafted server racks and cabinets.

Customization is our standard! We offer custom sizes, heights and even custom colors.

To learn more about some of our custom racks, click on a photo below.