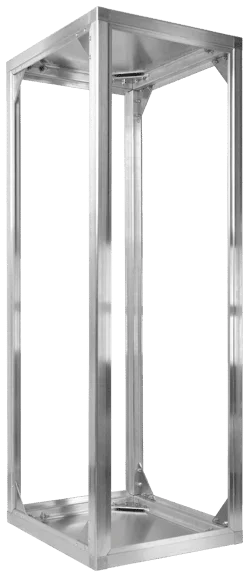

Aluminum Structural Framing System

Our heavy-duty aluminum Structural Framing System (SFS) is a simple method of designing and building frames and enclosures to special size and high strength requirements. This unique AMCO Enclosures system provides a selection of 14 aluminum extrusions (1.50″ OD) and 8 types of corner castings (0.125″ wall thickness). The flanges in the extrusions accommodate .625″ formed panels and .125″ flat panels (made upon request). The aluminum framing system accepts locking clips (provided standard) for permanent designs or non-locking clips (optional) for prototypes or planned disassembly. When reinforced with bolt-on gussets, SFS assemblies can meet MIL-STD-167-1 shock and vibration requirements. AMCO Enclosures’ aluminum structural framing is ISO9001 Certified. Also, our products are designed and manufactured in the United States. For our customers’ convenience, our aluminum structural framing system includes a 10-year warranty.

- ROHS Compliant

- ISO9001 Certified

- 10-Year Warranty

- Designed and manufactured in the USA

Accessories:

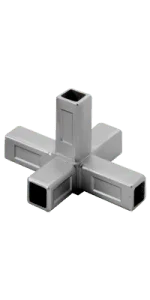

Castings

Castings are furnished with locking clips for assembly to extrusions. Special services available include: machining, hardware installation, marking and packaging.

Note: Casting legs are undercut when necessary to provide optimal fit (structural integrity not affected).

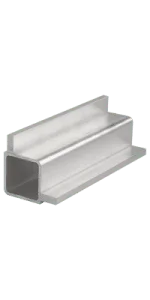

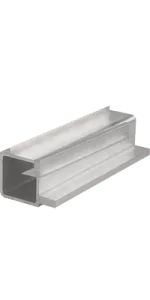

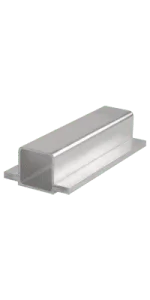

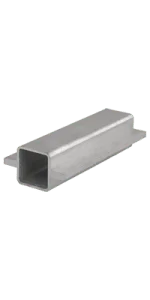

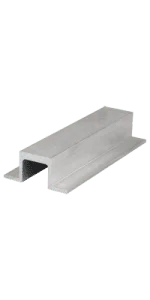

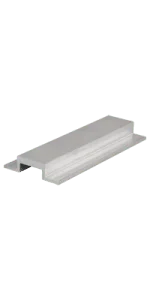

Extrusions

Maximum extrusion length is 10’. Extrusions are supplied without mounting holes. Extrusions will be pre-cut to length and mitered to 90° angles at no additional cost.

Note: Tolerances are in accordance with the aluminum association standards as applied to extruded shapes.

Other Accessories

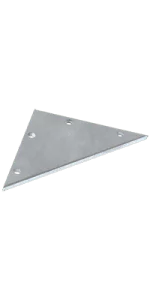

The addition of simple bolt-on 3/16″ (4.76mm) 6061T6 aluminum gussets provides reinforcement that will meet MIL-STD shock and vibration requirements.

The addition of simple bolt-on 3/16″ (4.76mm) 6061T6 aluminum gussets provides reinforcement that will meet MIL-STD shock and vibration requirements. 21 ga. 0.32″ (0.81mm) 1075 SAE soft spring clips are seated between the casting and the extrusion for permanent locking.

21 ga. 0.32″ (0.81mm) 1075 SAE soft spring clips are seated between the casting and the extrusion for permanent locking.

Non-Locking clips (optional) permit your HD Aluminum design to be assembled for trial purposes or for future disassembly.

Non-Locking clips (optional) permit your HD Aluminum design to be assembled for trial purposes or for future disassembly.

Spring type, corrosion resistant steel roll pins can be used with standard locking clips to provide a simple method of reinforcing the joint against axial strains in excess of 1,600 lbs.

Spring type, corrosion resistant steel roll pins can be used with standard locking clips to provide a simple method of reinforcing the joint against axial strains in excess of 1,600 lbs.